Our specialization in production processes allows us to

identify the most suitable technology for producing all types

of aluminum mechanical components, choosing from:

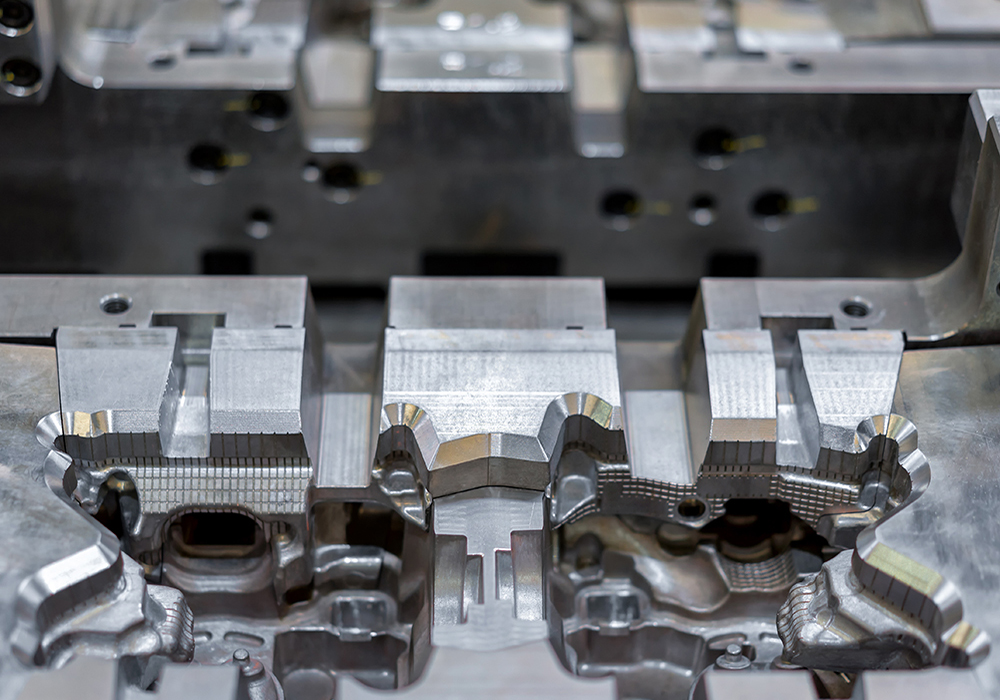

casting

,

hot pressing

, die casting, extrusion or directly from the bar.

The main factors that we take into consideration after having

extensively discussed with the customer are the following:

- Annual drafting -

Field

of use and mechanical characteristics

- Surface

finish required - Detail morphology to be realized

Only after a complete analysis we can orient ourselves towards

the Asian partner specialized in the process chosen for

production, with the certainty of reaching the required result

in the shortest possible time.

A great added value is the possibility to assemble, test,

paint, anodize and package the item we are commissioned in

customized packaging.

Our company

is structured to produce both small and large lots, managing

the programming of our customers and ensuring punctuality on

requested deliveries. The size of the castings can be from a

few grams up to 75 kg.

EDR Fittings guarantees rapid prototyping in

less than 30 days accompanied by detailed dimensional reports

and material analysis. (For food use, also transfer test DM

258 of 12/21/2010)

› Important cost reduction by obtaining a high quality and industrialized product.

› Possibility of creating products with shape complexity and undercuts in a single piece, eliminating costly machining or welding.

› Precision castings with very narrow dimensional tolerances.

› Elasticity of production lots without set-up costs.

› Low cost of equipment often amortized already with the first production order.

› Excellent quality surface finish and possibility to insert your company logo or code directly on the merger.

› Possibility to melt each material keeping the mechanical properties unchanged.