Rapid prototyping allows you to evaluate in detail how the component designed will really be. This will reduce costs, construction and design schedule of the product.

Why Rapid Prototyping?

Since ancient times, inventors, designers and creative people have always used a two-dimensional planto communicate and evaluate their ideas before putting them into practice. While in the past the first designers relied on parchment paper and compass, contemporary ones can make use of a veritable heap of design mediums. Nevertheless, the designer is never absolutely certain that what he sees on the screen isa faithful representation of the concept that he intends to carry out. Rapid prototyping is the most successful attempt to break through this barrier: the one to transform fleeting images into a solid and concrete object that can be touched and used together with other components.

Aims

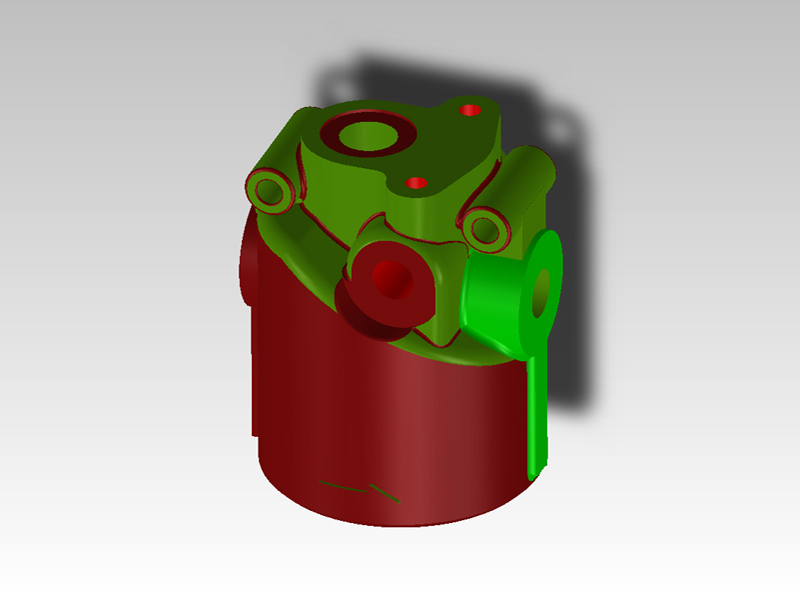

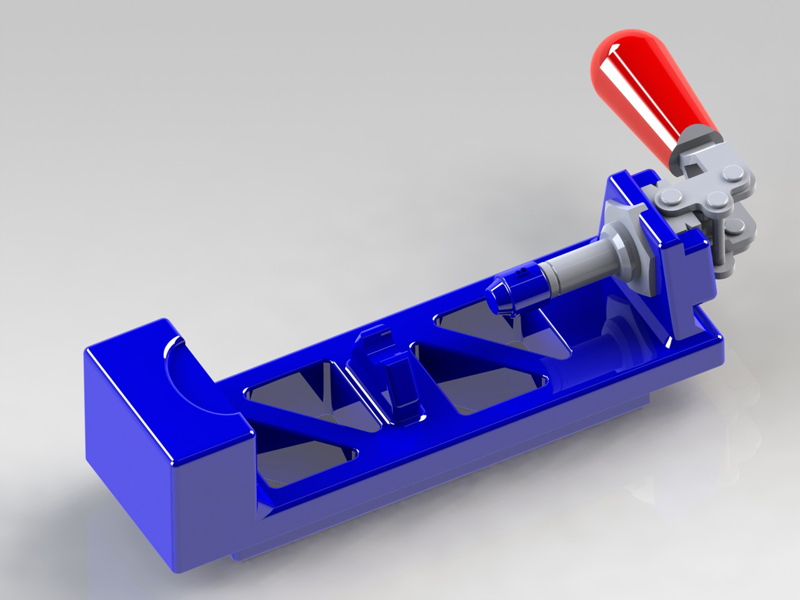

technological processes that are in continuous evolution,it intends to create plastic prototypes - ABS (Acrylonitrile but a dienestyrene)- starting from a 3D CAD mathematical model. The mechanical properties of the starting material allows to create components with a high mechanical strength which allow to make functional prototypes. Our staff is composed of mechanical engineers that provide engineering design and consultancy service.By using technological processes that are in continuous evolution,it intends to create plastic prototypes - ABS (Acrylonitrile but a dienestyrene)- starting from a 3DCAD mathematical model. Our staff is composed of mechanical engineers that provide engineering design and consultancy service.