EDR Fittings is a reliable partner for global industries to deliver precision components with cost-effectiveness and uncompromised quality. With over two decades of experience, the company has mastered the art of managing complex projects in Asian markets, leveraging its partnerships with certified manufacturers in China and India.

EDR Fittings has positioned itself as a leading partner for industries seeking high-quality components. Their expertise lies in microfusion and pneumatics. They delivering innovative solutions tailored to diverse needs.

This blog explores how EDR Fittings redefines manufacturing through its tailored solutions, high-quality production processes, and customer-centric approach.

A Comprehensive Casting Process

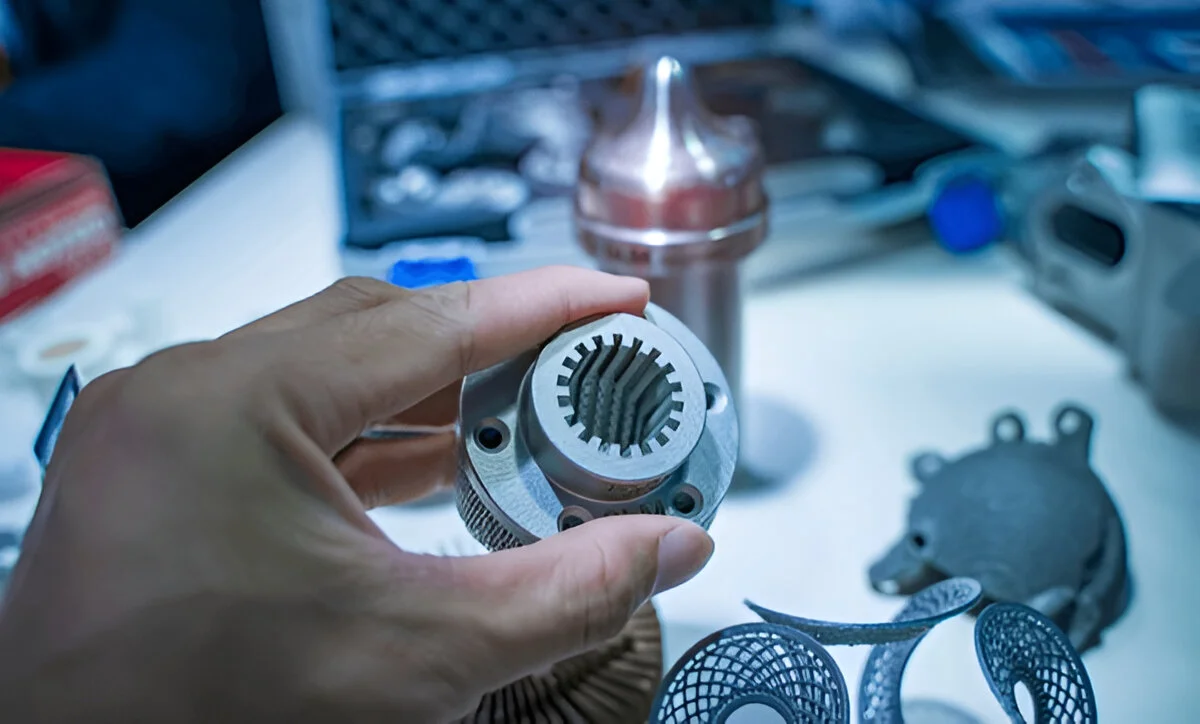

EDR Fittings specializes in turnkey casting solutions, focusing on micro-casting, die casting, and mechanical machining. The company collaborates with highly skilled Asian manufacturers who excel in advanced technologies like investment casting (lost wax casting) and liquid forging. These methods allow the production of intricate components for industries ranging from automotive and aerospace to medical and marine sectors.

By employing the lost-wax casting technique, EDR Fittings achieves exceptional detail and precision. This method is ideal for producing lightweight, corrosion-resistant parts using materials such as stainless steel, aluminum, and carbon steel. For projects requiring larger and more durable parts, the company employs sand casting or lost foam casting, enabling the manufacture of castings weighing several tons.

The Advantages of Microfusion

Microfusion is a precise and versatile manufacturing process. It enables the production of intricate geometries and tight tolerances that traditional methods struggle to achieve. This process is ideal for lightweight parts, even in small production batches.

What makes microfusion stand out? Its high repeatability, superior surface finish, and cost efficiency. For industries demanding precision and reliability, microfusion is a game-changer.

A One-Stop Solution for Components

EDR Fittings offers a unique advantage. It is a single point of contact for all component needs. Their approach combines attention to detail with a deep understanding of customer requirements. From design to production, EDR ensures seamless project execution.

With a strong presence in Asia, EDR collaborates with trusted partners to manage various industrial processes. They specialize in materials like aluminum, steel, and carbon. This flexibility allows them to deliver solutions that are both practical and cost-effective.

Supporting the Pneumatics Industry

The pneumatics sector has seen steady growth, and EDR Fittings is at its forefront. They manufacture stainless steel components, cylinder heads, and air treatment parts. Their commitment to quality has earned the trust of major industry players in Italy, Germany, Spain, and France. One best feature is their dedication to localized support. EDR's team in China oversees production. They ensure adherence to strict quality standards. They meet the expectations of even the most demanding clients by combining global expertise with localized presence.

Contributing to Iconic Projects

EDR Fittings' capabilities extend beyond standard components. They played a pivotal role in the construction of the Al Wasl Plaza dome for Expo 2020 Dubai. This architectural marvel required high-precision microfusion parts, all produced by EDR to meet stringent international standards.

Quality Without Compromise

One of EDR Fittings' core strengths is its adherence to strict quality standards. All manufacturing partners are audited regularly to ensure compliance with ISO 9001 certifications and rigorous quality agreements. This ensures that components not only meet but exceed customer expectations in terms of durability, performance, and precision.

To further enhance product reliability, the company employs additional treatments such as pickling, passivation, and electropolishing. These techniques significantly improve corrosion resistance, making components suitable for demanding environments like marine applications.

Tailored Solutions for Every Need

Unlike many manufacturers, EDR Fittings does not rely on standardized production. Instead, it offers customized solutions, enabling clients to create components tailored to their specific requirements. The company provides technical consultations to identify the most efficient manufacturing techniques for each project, ensuring optimal results. Whether a client requires small-batch prototypes or large-scale production, EDR Fittings delivers with flexibility and precision.

The use of 3D printing for wax molds in prototyping adds another layer of customization. This innovative approach reduces initial tooling costs and allows for rapid iterations during the development phase.

Cost-Effective Production in Asia

EDR Fittings leverages its long-standing relationships with Asian manufacturers to offer competitive pricing without sacrificing quality. Advanced European machinery and skilled local labor enable the production of high-quality components at a fraction of the cost typically associated with European manufacturing.

Moreover, EDR Fittings provides end-to-end management, handling everything from supplier selection and order supervision to customs clearance. This streamlined process minimizes risks for clients and ensures timely delivery of finished products.

Sustainability and Innovation

In today's eco-conscious world, sustainability is a priority for EDR Fittings. The company actively works to reduce waste and energy consumption in its manufacturing processes. Innovations like liquid forging further demonstrate EDR Fittings' commitment to environmental responsibility, as this process reduces material waste and enhances product strength.

Additionally, EDR Fittings integrates Industry 4.0 solutions into its operations. Real-time production monitoring and automation. This not only improves efficiency but also enables the company to adapt quickly to evolving customer demands.

Why Choose EDR Fittings?

- 1. Experience and Expertise: With over 20 years in the industry, EDR Fittings has a proven track record in managing complex projects.

- 2. Global Partnerships: Collaborations with top-tier Asian manufacturers ensure high quality at competitive costs.

- 3. Customization: Tailored solutions address unique client needs, from material selection to manufacturing techniques.

- 4. Sustainability: A focus on eco-friendly practices aligns with modern industry standards.

- 5. Customer Support: From initial consultation to final delivery, EDR Fittings offers comprehensive support.

EDR Fittings exemplifies how precision engineering and global collaboration can redefine manufacturing. The company combines state-of-the-art technologies with sustainable practices and delivers high-quality components tailored to the most demanding industries. Whether you need intricate micro-castings or robust die-cast parts, EDR Fittings is the partner you can trust for a seamless, cost-effective production experience.