Turning an idea into reality requires a reliable and efficient manufacturing process. Whether designing a new car part, a medical implant, or an aerospace component, precision and speed are important. This is where investment casting plays a crucial role in rapid prototyping.

Investment casting allows manufacturers to create highly detailed metal prototypes quickly. It provides accuracy, flexibility, and cost-effectiveness, making it a top choice for industries looking to test and refine their designs before mass production.

In this article, we will explore how investment casting supports rapid prototyping, its benefits, and how it compares to other prototyping methods.

What is Investment Casting?

Investment casting is also known as lost-wax casting. It involves creating a wax model of the desired part. This wax model is then coated with a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity. Molten metal is poured into this cavity to form the final part.

This process has been used for centuries. Today, modern technology has made it more efficient and precise. It is ideal for creating complex and detailed components.

The Role of Investment Casting in Rapid Prototyping

Rapid prototyping is the process of quickly creating a working model of a product. It helps manufacturers test designs before mass production. Investment casting plays a crucial role in this process.

Here’s how investment casting is used for rapid prototyping:

1. Quick Design Testing

With investment casting, manufacturers can create prototypes quickly. They can test different designs without committing to expensive tooling. This allows for fast improvements and adjustments.

Cost-Effective for Small Batches

Investment casting is a great choice for small production runs. It is more affordable than other metal-forming methods like machining. This makes it perfect for prototyping, where only a few parts are needed.

3. High Precision and Detail

One of the biggest advantages of investment casting is its accuracy. The process captures fine details with minimal errors. This is important for prototypes that require precise dimensions.

4. Wide Range of Materials

Investment casting supports a variety of metals. Manufacturers can test prototypes using different materials. This helps them choose the best option for strength, durability, and performance.

5. Smooth Surface Finish

Prototypes made with investment casting have a smooth surface. This reduces the need for extra finishing work. A smooth finish is crucial for testing the look and feel of a product.

Rapid Prototyping Types

Rapid prototyping involves various techniques to create physical models quickly. Some of the most common types include:

1. 3D Printing (Additive Manufacturing)

This method builds prototypes layer by layer using materials like plastic, resin, or metal. It is fast, cost-effective, and ideal for complex designs.

2. CNC Machining

CNC machining removes material from a solid block using cutting tools. It offers high precision and strength, making it suitable for functional prototypes.

3. Stereolithography (SLA)

SLA uses a laser to harden liquid resin layer by layer. It is known for producing smooth and detailed prototypes.

4. Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material, creating strong and durable prototypes. It works well for functional testing.

5. Injection Molding

Injection molding is used for creating multiple prototypes with consistent quality. It is ideal for mass production testing.

Rapid Prototyping Applications

Rapid prototyping is used in many industries to speed up product development. Some common applications include:

- 1. Automotive Industry: Car manufacturers use rapid prototyping to test new parts and improve vehicle design.

- 2. Aerospace Industry: Aerospace companies create prototypes to test aerodynamics, safety, and durability.

- 3. Medical Field: Medical professionals use rapid prototyping to develop prosthetics, implants, and surgical tools.

- 4. Consumer Electronics: Tech companies use prototypes to test new devices, from smartphones to wearables.

- 5. Industrial Manufacturing: Factories create prototypes to refine machinery and improve production processes.

The Process of Investment Casting for Rapid Prototyping

The investment casting process for rapid prototyping follows these steps:

- Step 1: Create the Wax Model A wax model of the prototype is created. This can be done using 3D printing or traditional methods. 3D printing allows for faster production of complex designs.

- Step 2: Assemble the Wax Tree If multiple parts are needed, they are attached to a wax tree. This helps with efficient casting.

- Step 3: Create the Ceramic Shell The wax model is dipped into a ceramic slurry. Multiple layers are added to create a strong shell. This shell must dry and harden before the next step.

- Step 4: Remove the Wax The hardened shell is heated to melt and remove the wax. This leaves a hollow ceramic mold.

- Step 5: Pour the Metal Molten metal is poured into the mold. It fills the cavity left by the wax model.

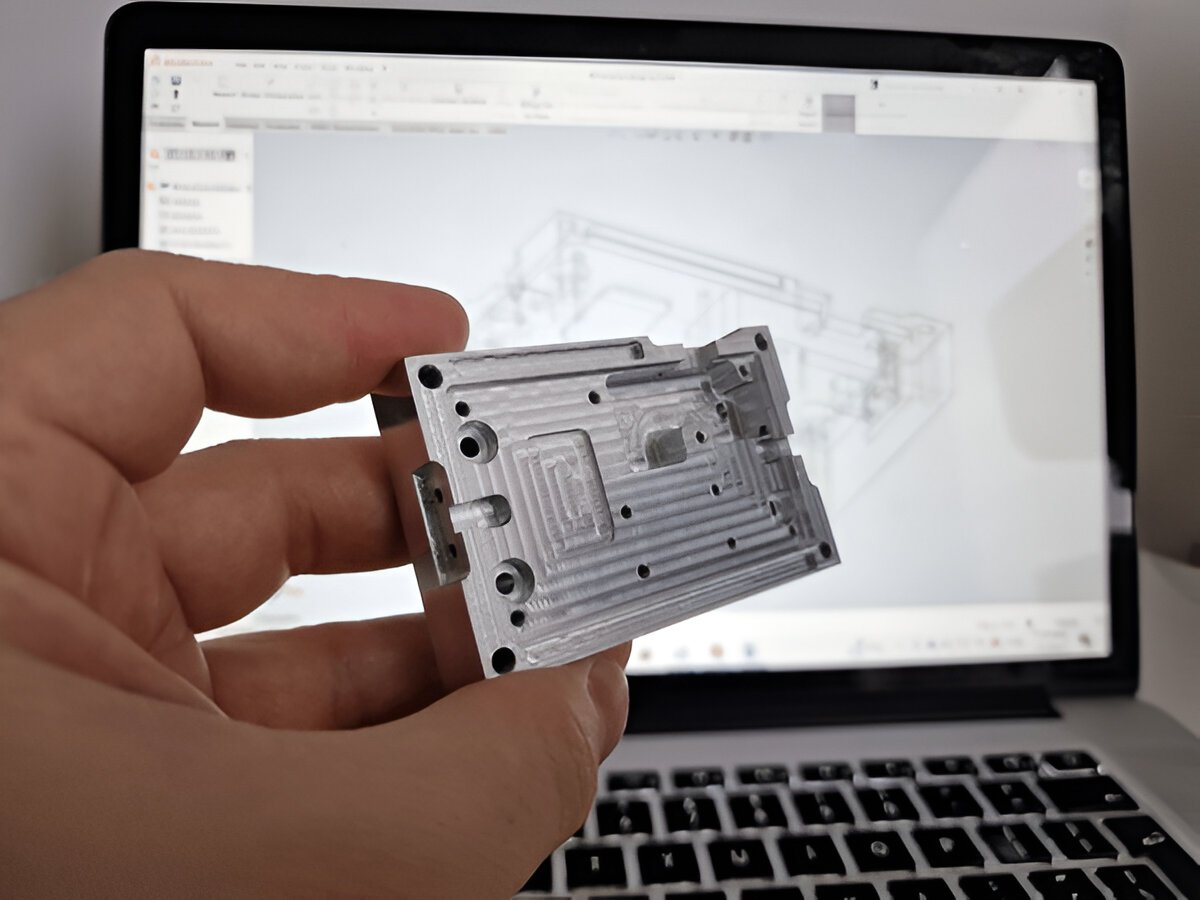

- Step 6: Break the Ceramic Shell Once the metal cools and solidifies, the ceramic shell is broken away. This reveals the final metal part.

- Step 7: Finishing Touches The part undergoes finishing processes like polishing, machining, and heat treatment. This ensures the prototype meets design specifications.

Advantages of Using Investment Casting for Prototyping

Investment casting offers many benefits for rapid prototyping. Here are some of the key advantages:

- 1. Complex Geometries This process can produce intricate and detailed shapes. It is ideal for prototypes with complex designs.

- 2. High Accuracy Investment casting delivers precise dimensions. This reduces the need for adjustments in later production stages.

- 3. Versatile Material Choices Manufacturers can test different metals, including aluminum, stainless steel, and titanium.

- 4. Reduced Material Waste Unlike machining, which removes material, investment casting minimizes waste. This makes it a cost-effective and sustainable option.

- 5. Faster Production Times With advancements like 3D printing, wax models can be created quickly. This speeds up the prototyping process.

Comparing Investment Casting with Other Prototyping Methods

Investment casting is not the only method for rapid prototyping. Let’s compare it with other common techniques.

| Method | Advantages | Disadvantages |

|---|---|---|

| 3D Printing | Fast, cost-effective, complex shapes | Limited material choices, weaker strength |

| CNC Machining | High precision, strong materials | Expensive for complex shapes |

| Sand Casting | Good for large parts, lower cost | Less precision, rougher surface | Investment Casting | High detail, smooth finish, strong materials | Longer process time |

Each method has its pros and cons. Investment casting stands out for its balance of precision, material variety, and cost-effectiveness.

Investment casting is a powerful tool for rapid prototyping. It allows manufacturers to test designs quickly and efficiently. With high accuracy, smooth finishes, and material versatility, it is a top choice for creating metal prototypes.

As technology advances, investment casting is becoming even more efficient. The integration of 3D printing with this process is making it faster and more cost-effective. If you need high-quality metal prototypes, investment casting is a great solution.